Fab Labs, Makerspaces, innovation centers and workforce training programs have specific demands for digital fabrication equipment. In most cases, a number of people from varied backgrounds and experience levels operate the machines especially in open access or membership settings, and the machines are in frequent use, often running long prints overnight. In addition, many of these types of fabrication laboratories are run by non-technical staff, including librarians, teachers, and museum curators or IT staff who have not worked with hardware. For these user groups, the key equipment parameters need to be ease of use and reliability, in order to foster interest in advanced technology and New Collar Jobs for Industry 4.0.

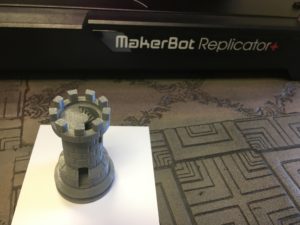

Fab Lab Hub was fortunate to receive a Replicator+ from MakerBot to test for our own fab labs at the Santa Fe Business Incubator and the Santa Fe Community College Innovation Center, both in New Mexico, and for the North American Digital Fabrication Alliance. And after several years of the Fab Lab Network experiencing issues with MakerBot 3D Printers, I am happy to report that our initial tests were quite positive.

Lauren Goglick, MakerBot’s General Manager for North America, explained to me that the company had taken seriously the need for improved performance and reliability. Two full years were spent listening to customers and responding to their needs. MakerBot says that the Replicator+ “prints 30% faster than its predecessor and offers a 25% larger build volume”. But most importantly for us, in order to achieve greater reliability and precision it features “improved hardware, like a redesigned gantry and z-stage. To ensure consistent performance, the new 3D printers and all of their subsystems were re-engineered and rigorously tested for 380,000+ hours across multiple facilities.”

The time, focus and testing that went into the redesign were evident when we tried the Replicator+ that was released last fall. Details will follow below, but in general, the Replicator+ was:

- very easy to set up, taking me about 10 minutes from unpacking to starting printing [do keep in mind I’ve been 3D printing for a very long time on a wide variety of machines so it might take longer for someone new to the technology]

- of sturdy construction yet easily portable

- I especially liked the magnetic Smart Extruder which installed in literally a snap

- software was easy to install and very user friendly

- test pieces including a functional prototype with moving parts printed very well

- the machine was quiet and interestingly, seemed to generate less fume odor than other machines I’ve used even though I was running it beside me on my desk

- printed every time, and I experienced no extruder clogging in a month of daily use even when changing filament which is often when clogging occurs

- it successfully ran 27 hour prints with no failures, and the ability to check the machine remotely on my phone was convenient

- the 100 micron [0.0039 inch] layer resolution was adequate for most of my print requirements but fancier, more delicate designs would need a higher resolution option

- eliminating the need for print bed adhesion assists is a big plus but I did find it took some work to remove some of the more delicate prints despite the Flexible platform.

Here are the details from our experience.

Out of the box, the Replicator+ performed well. Quick start instructions and the manual were clear and easy to follow. The magnetic print head was a cool design. All extrusion-based 3D Printing systems clog at some point – it’s a part of all extrusion, even in older, non-3D Printing methods like extruding PVC pipe. Un-clogging can take time and is not convenient if you’re in the midst of teaching. I plan to get a 2nd print head as Fab Lab Hub teaches a number of classes and workshops. If you have a clog, pop out the old Smart Extruder, install a new one in a few seconds and continue teaching. The clog can then be handled when it’s convenient for everyone.

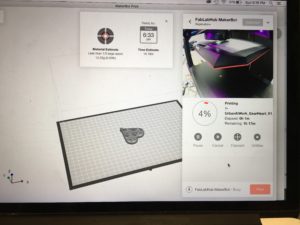

The software was intuitive but again I understood how .stl files have to be converted to the specific 3D Printer’s machine code in order to drive the printer. New users might not realize the step needed, so it might take a little longer to set up, but should go smoothly by following the well-written manual. Changing print settings such as temperature or layer thickness was easy in the software, but as with all 3D Printers, some experimentation is required to optimize designs for a specific machine.

The initial test designs that are loaded into the machine ran smoothly. Auto-leveling was also a nice feature. With the new Grip Surface, prints are supposed to adhere better, resulting in reduced warping and curling, which they did. So many fab labs run into safety issues using things like flammable hair spray or the ubiquitous blue tape to increase build plate adhesion so this is easier to set up and, in my opinion, safer. But I did find it difficult to remove some of the prints despite the flexible feature and broke a few of the more delicate designs in my ardor to remove them.

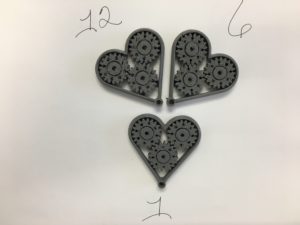

Printing a functional prototype is important for our work in workforce training, so I tried a heart with 3 interlocking gears designed by Urban at Work.

The single print shown on the right at the bottom printed perfectly, easily separated from the sacrificial layer requiring no post-printing clean up and the gears moved freely. Next I multiplied the design to fit 6 parts on the build plate and results were similar to the single part print. However, when I moved to printing 12 parts the quality of the print was less precise and the gears adhered too strongly to the sacrificial layer, making removal difficult. A fair amount of cleanup was needed to remove excess material left from the sacrificial layer but that then allowed the gears to move freely.

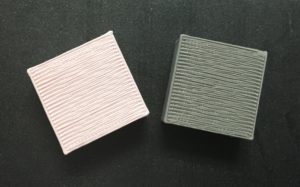

One concern is the labels on the printer warning that using other brands of filament voids the warranty. MakerBot has always been at the center of the Maker Movement which champions an open source philosophy. Not one to be deterred, I tested filament from our collaborator 3D Print Life and had excellent results. The two test cube designs that come with the Replicator+ yielded identical results. I was also able to print the functional prototype with similar results. Do keep in mind that if an issue ensues you’ve voided the warranty.

All in all, I was pleasantly surprised by the new MakerBot Replicator+ and plan to use it regularly in our New Collar Workforce digital fabrication training programs, as well as in the Fab Labs we operate in New Mexico. While the price is higher than for other FDM tabletop 3D Printers, heavy use by multiple users requires a machine that is not at the low end of the quality spectrum. It really is nice to see a manufacturer listen to customers and put in the time and energy to create a strong product!

All in all, I was pleasantly surprised by the new MakerBot Replicator+ and plan to use it regularly in our New Collar Workforce digital fabrication training programs, as well as in the Fab Labs we operate in New Mexico. While the price is higher than for other FDM tabletop 3D Printers, heavy use by multiple users requires a machine that is not at the low end of the quality spectrum. It really is nice to see a manufacturer listen to customers and put in the time and energy to create a strong product!

Review by Fab Lab Hub Founder, Sarah Boisvert

@FabLabHub on Twitter