Problem Statement

I wanted to do a project that had a musical component. I chose to explore how the geometry of a resonant cavity affected the sound it produced.

Proposed Solution

By printing multiple designs, both pre-existing and designed myself, and comparing the sounds that each produces, I will determine how the size and shape of a design affects the tones it makes.

Design Process

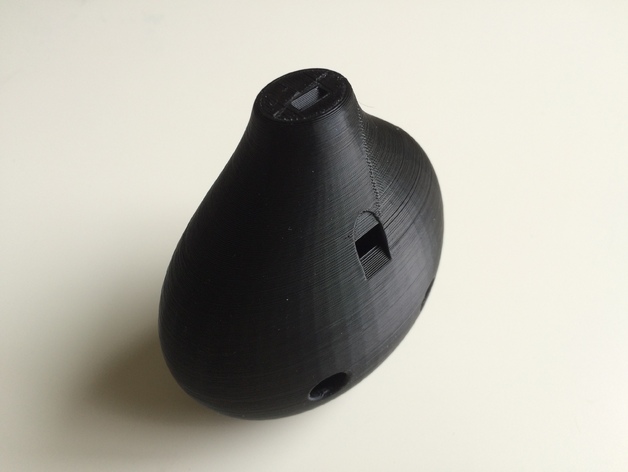

I began by researching how other people had approached the problem. I found several designs for ocarinas on Thingiverse and printed them. I also researched Helmholtz resonators, which are simple spherical devices that produce pure tones. Because I had little CAD experience, and because the design was simple, I chose to design my project based off of the Helmholtz resonator. I used the free software TinkerCAD to model it.

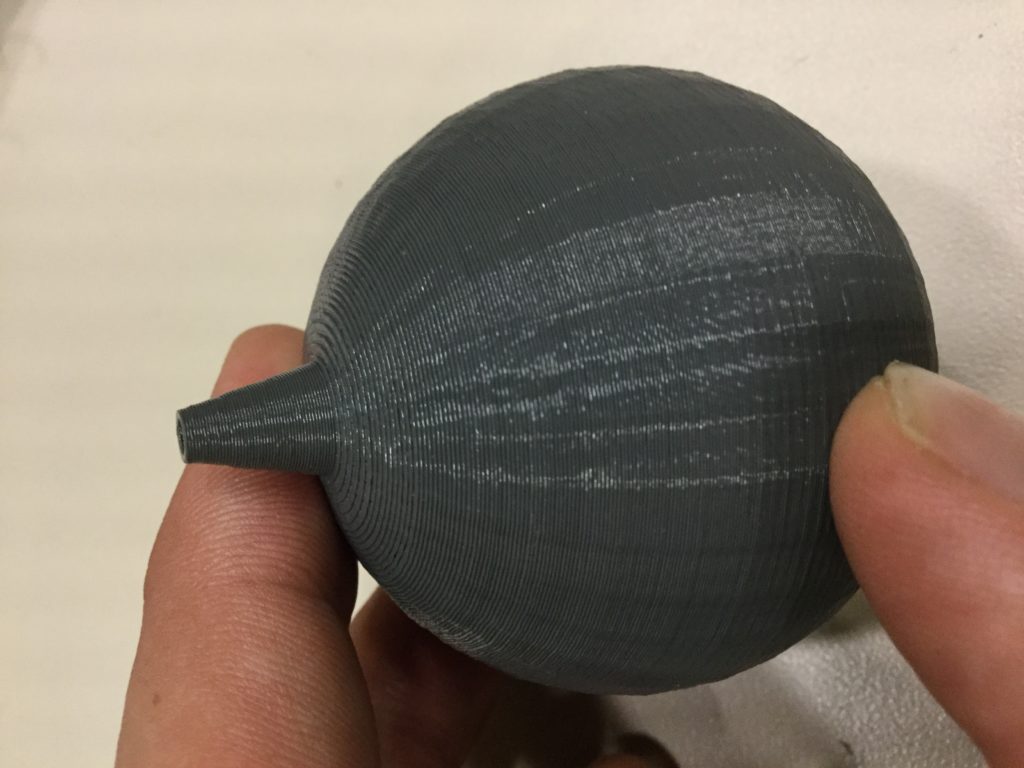

I took an iterative approach to the design process, first creating a design, then testing it, then adjusting the design based on the results of the tests. To save time and materials, I focused only on one piece of the design at a time, and I created scaled-down versions until I was ready to print a final design.

Problems Encountered

Although the initial version of the Helmholtz resonator printed well, but I discovered that the earpiece was too short to fit in one ear. After redesigning the earpiece, I printed it by itself to save on both time and material. After verifying the earpiece was the correct size, I printed the entire model again, this time scaled up to its full size.

Unfortunately, the model produced no sound when I held it up to my ear. At this point, I decided to modify the scope of the project, instead changing the design to accommodate a trombone mouthpiece, which I had on hand.

Lessons Learned

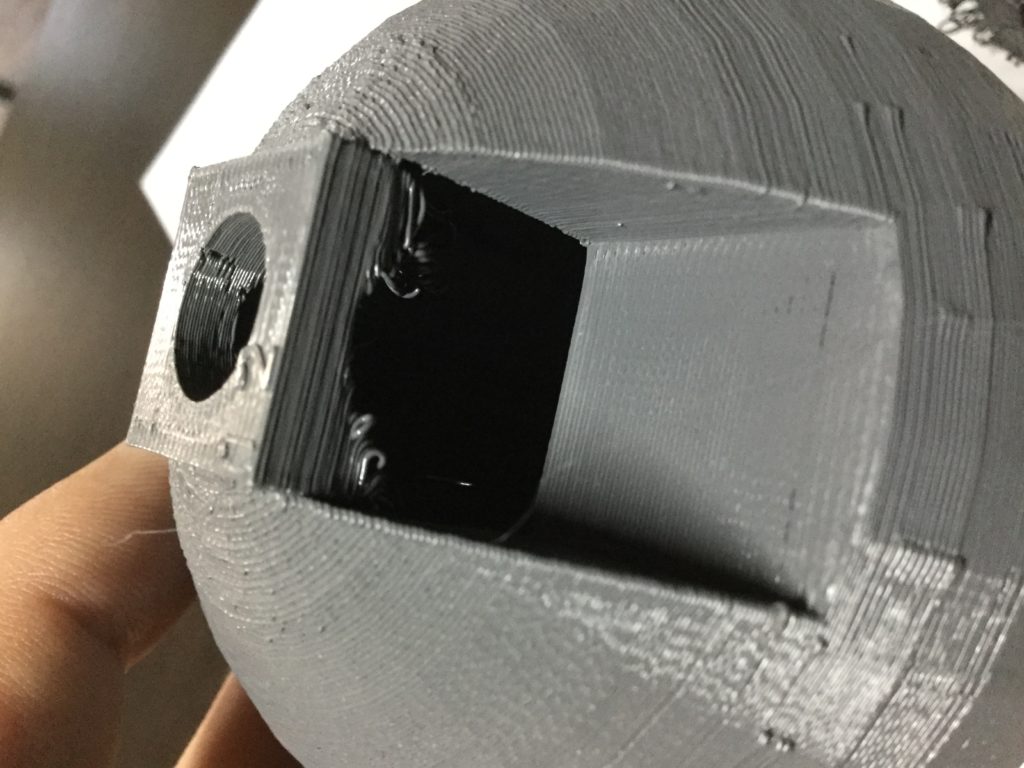

1. Prints will rarely come out exactly as you expect. Deviations often come in the form of minor superficial flaws (e.g. misplacements of material), but may constitute more serious problems (e.g. holes in the part). The Makerbot seems to have particular trouble at the bottoms of parts, where it often makes messes.

2. Printing scaled-down versions of parts is an effective way to test ideas without the time and material costs of the full-size version. It also allows for multiple parts to be printed at once, which can save time.

3. Caveat: Just because a part prints well at small scale does not necessarily mean it will work well at a larger scale. For instance, large cavernous parts inside which it is not possible to put supports.

4. The ability to rapidly print prototypes means that adopting an iterative design process allows you to move quickly through your development process.

5. Likewise, for functional designs, modular design proves an effective method of testing individual pieces of the design without committing to the time required for the full build. If your design can be divided into different functional parts, and you can identify one of those parts as the most likely point of failure, you can focus your time on that part without printing the whole model.

6. Your final project does not have to be a single piece, and printing multiple pieces and fitting them together later lends itself well to the modular design process mentioned above. It also means that your final product can be larger than the maximum size governed by the printer’s build plate.

7. Certain parts are not well-suited to 3D printing, including very thin parts and parts that need to be smooth. You may simply be able to tweak these parts to make them print successfully, or you may be better off using a different process for these parts (or even for small modifications, like drilling holes).

8. Internal supports inside hollow, closed models cannot be easily removed. If you absolutely cannot have supports inside your model, be aware that this could compromise its integrity.

9. Although the print preview allows you to see what the inside of a model should look like, there is no way to see the inside of a closed model without cutting it open and thus destroying the part. Although you can always print the part again, you cannot guarantee that it will come out the same way, due to the nature of the process.